EN

EN

Request A Quote Questions & Comments After Sales Services Resource Center

EN

EN

Request A Quote Questions & Comments After Sales Services Resource Center

Polypropylene granules are small materials which could be plastic are widely used in several industries, such as packaging, automotive, construction, and much more, similar to the JIAFAN's product like abs plastic granule. These granules provide a range wide of, including superior real properties, cost-effectiveness, and recyclability. we explore the innovation, safety, use, quality, and application of polypropylene granules.

Polypropylene granules are notable for their innovation when it comes to their properties that are superior are real high stiffness, temperature resistance, and low-density, the same as hdpe raw materials made by JIAFAN. These features make polypropylene granules ideal for changing materials that are conventional as metals and glass in various industries. Additionally, polypropylene granules are developed to meet market different, such as food-grade, automotive-grade, and electrical-grade.

Safety the most crucial aspects of almost everything, as well as the JIAFAN's polyethylene granules. Polypropylene granules have been tested for safety and from now on have already been verified to be non-toxic, non-carcinogenic, and non-reactive with any medication or meals. Polypropylene granules may additionally be free from any materials being animal-derived. Thus, they are suitable for used in meals packaging, medical products, and other applications that can easily be painful and sensitive.

Polypropylene granules are versatile that will be used for different applications, such as injection molding, blow molding, thermoforming, and more, same with the plastic granules developed by JIAFAN. Polypropylene granules may be molded into various sizes and shapes, such as containers, cups, automotive parts, plus much more. Additionally they offer excellent chemical opposition and therefore are also resistant to acids, bases, and solvents, making them worthy of harsh environments.

Polypropylene granules are easy to use and need processing time minimal, along with JIAFAN's product hdpe 5110. To make use of polypropylene granules, they must first be melted using a processing device plastic. The melted material will undoubtedly be cooled and molded towards the desired form having an injection molding or blow molding process. It is worth noting that the heat and stress utilized during the melting process will vary with regards to the grade and application for the polypropylene granules.

We're polypropylene granulesproviding an excellent product after-sales services, as well as cutting costs and increasing effectiveness. This will help us help in the rapid growth of our company. Continuously provide high level service assurance to enhance ,Always put the needs of customers first .

Our company was founded in 2017, we focus on the manufacturing of plastic and rubber particles. Our clients can select from a wide range of plastic granules like extrusion, film coating, optical and food-contact grades. Our factory is a strong and experienced business. There a myriad of polypropylene granulesand granulators with annual production of 5000 tonnes.

Our products are polypropylene granulesa variety of countries including Northern Europe, Southeast Asia, North America, South America, Southern Europe, Eastern Europe. Goods can be transported by sea, land or air. Logistics transportation from us is fast and convenient, safe and efficient and has been praised by clients many countries around the globe.

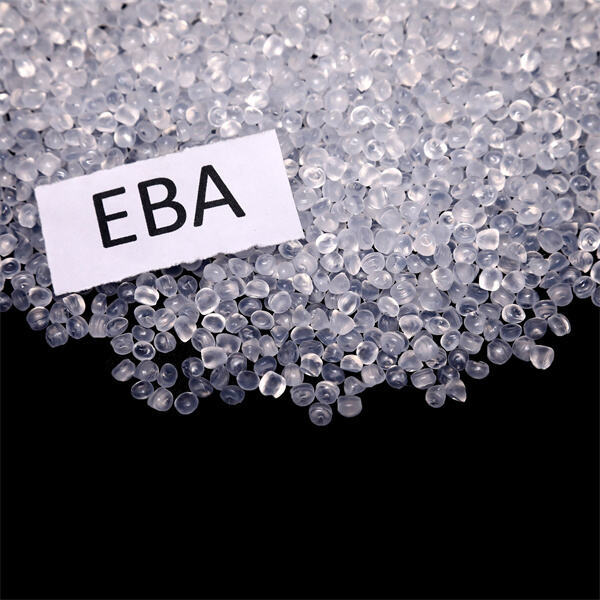

The main activity of the company is manufacturing and sales of plastic granule raw materials. polypropylene granulesmain products include all EVA EVOH PCTG PESU POE PC ABS PEEK PVC PVA HDPE LDPE PP EPS GPPS Paraffin and other plastic granules.We also accept customized production (sample customization/parameter customization).

Copyright © Hebei Jiafan Trading Co., Ltd. All Rights Reserved