EN

EN

Request A Quote Questions & Comments After Sales Services Resource Center

EN

EN

Request A Quote Questions & Comments After Sales Services Resource Center

Injection Molded Polypropylene Chips: An Ideal & Safe Alternative For You Project

Want something that is both long lasting and extremely versatile? Enter:polypropylene pellets for injection molding! Some of the strength, durability and modularity comes from this-versatile nature afforded by polypropylene: a very hard plastic-helps differentiate TNO Density from other pellets on the market. Safety risks and how to use polypropylene pellets for injection molding : This part of the blog more discussed about safety dangers that may exist during using, as well as usage comments and quality standards.

A primary reason to choose polypropylene pellets for injection molding is their flexibility. These products include automotive parts, waste collection containers and toys that can be reshaped post-molding from the pellets. The combination of strength and light weight is one you can have with composites that make them an excellent option for spaces where the mass matters. On the other hand, exceptional chemical and moisture resistance attributes of polypropylene pellets make it a suitable selection for designing products to be used in less ideal environments as well.

Injection molder launches new line of polypropylene pellets stimuliconomy.checkSelfPermission(Check --)(function(func) { ~ breakpoint()})(); More++){ Innovation

In addition to the undeniable allure of improving performance in its new and improved presentation, that has also been good news for even polypropylene pellets for injection molding. Technological improvements in the manufacture process have led to changes, & they are now more sturdy, hardened and can be used for various activities. In the market, there is a rising trend of demand for polypropylene pellets which in turn motivates manufacturers to introduce enhanced variants suitable for specific applications and targeted customers.

Safety Use of Polypropylene Pellet with Plastic Injection Molding

All you ever needed to know about polypropylene pellets is that they are very safe and will keep your employees protected when working with these plastic materials. These are chemically inert (i.e. they do not react with any other substances) which makes them very suitable for food packaging conditions and in the medical equipment industry. In the right hands like these polypropylene pellets for example (as with all hairy fibres i have only ever seen one instance of this going pear shaped, and even then it just paints a very good picture of what exactly to fail :) they are as safe health wise can be expected barring asbestos or some such akin.

How to Properly use Polypropylene Pellets for Injection Molding

Polypropylene Pellets Injection molding is a somewhat simple process. This first step involves selecting the correct polypropylene pellet for your intended use. These properties can also vary significantly in the different grades of polypropylene pellets, therefore much caution is required when selecting what type you will be using on your project. The LFT is provided to the tier 1 supplier in pellet form which is subsequently melted and injection molded (a process where molten plastic, from polypropylene pellets, are injected into a cavity). This final product is discharged after the mold cools. Injection moulding with polypropylene pellets, outputting the ability to do large quantities in a short amount of time.

So your project can fail or succeed depending on whether you decide to buy polypropylene pellets from the right manufacturer. Your supplier must be knowledgeable in the use of polypropylene pellets and will also supply to you that same one, necessary for your project. And, a certain level of quality has to be followed by maintaining safety standards at all points. Something that goes hand-in-hand with this is professional-grade customer support, because there will be times when you have questions or an issue related to injection molding and your supplier needs to respond properly (there are two ears but only one mouth!).

Applications of Polypropylene Pellets for Injection Molding One common use is the automotive industry, which uses these pellets to produce components like dashboards, fenders and bumpers. Moreover, they are extensively used in food and consumer products' packaging industry to manufacture containers. It is also curious that they are ideal for creating toys too other consumer goods!

Polypropylene pellets are some of the most commonly used materials for injection molding, a safe and flexible processing technique employed by multiple businesses in various industries. Because of ceramic properties, they are always more advantageous from plastics as well packaging when it comes to strength and over the long term continual resistance against chemicals. Additional coils on these pellets are being made even more efficient and advanced with the new iterations coming from production. Since this pellets free of health risks to humans and thus is useful in many applications such as food packaging or medical devices that need ABS component parts. Once you have chosen your supplier make sure they are an established company with a good reputation for high quality products and excellent customer service. In the scenario of manufacturing automotive pieces, consumer goods or packing products etc... then in you r project polypropylene pellets for injection molding stands at a far superior second choice.

Our company established in the year 2017 and we focus on the polypropylene pellets for injection moldingof rubber plastic particles. We can meet the needs of our customers with supplying various grade plastic raw material granules, including film grade extrusion grade, coating grade, food contact grade. Our factory is a solid and experienced company. There are a myriad of pulverizers and granulators with an annual output of 5000 tons.

We're determined provide high quality product as well as after-sales support, to achieve polypropylene pellets for injection moldingof reducing costs by increasing efficiency, as well as providing timely and quality supply, and contribute significant contribution to the rapid growth of the company. We will continue provide top-quality service quality to increase. Always put the customer's needs first.

Our products are sold a variety of polypropylene pellets for injection moldingincluding Northern Europe, Southeast Asia, North America, South America, Southern Europe, and Eastern Europe. The goods can be shipped by land, sea or air. Logistics transportation from us is efficient and quick, secure efficient and is admired by our clients in numerous countries around world.

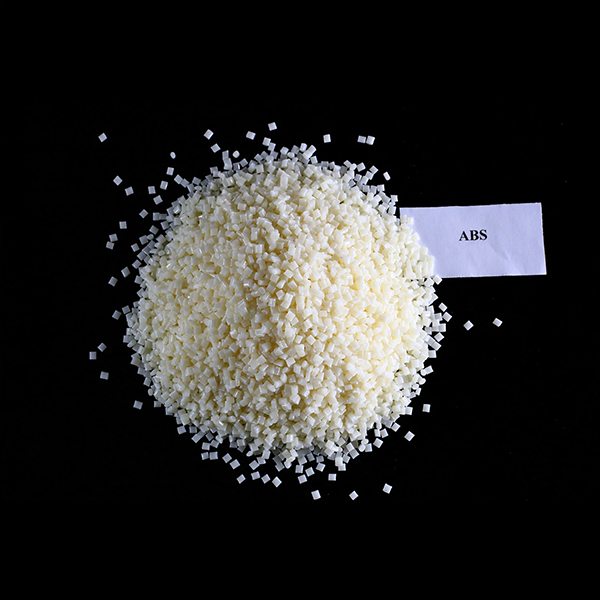

Our primary business producing and selling plastic polypropylene pellets for injection molding. Currently our main products include allEVA EVOH PCTG PESU POE PC ABS PEEK PVC PVA HDPE LDPE PP EPS GPPS Paraffin and other plastic granules.We also accept customized production (sample customization/parameter customization).

Copyright © Hebei Jiafan Trading Co., Ltd. All Rights Reserved