Low Density Polyethylene

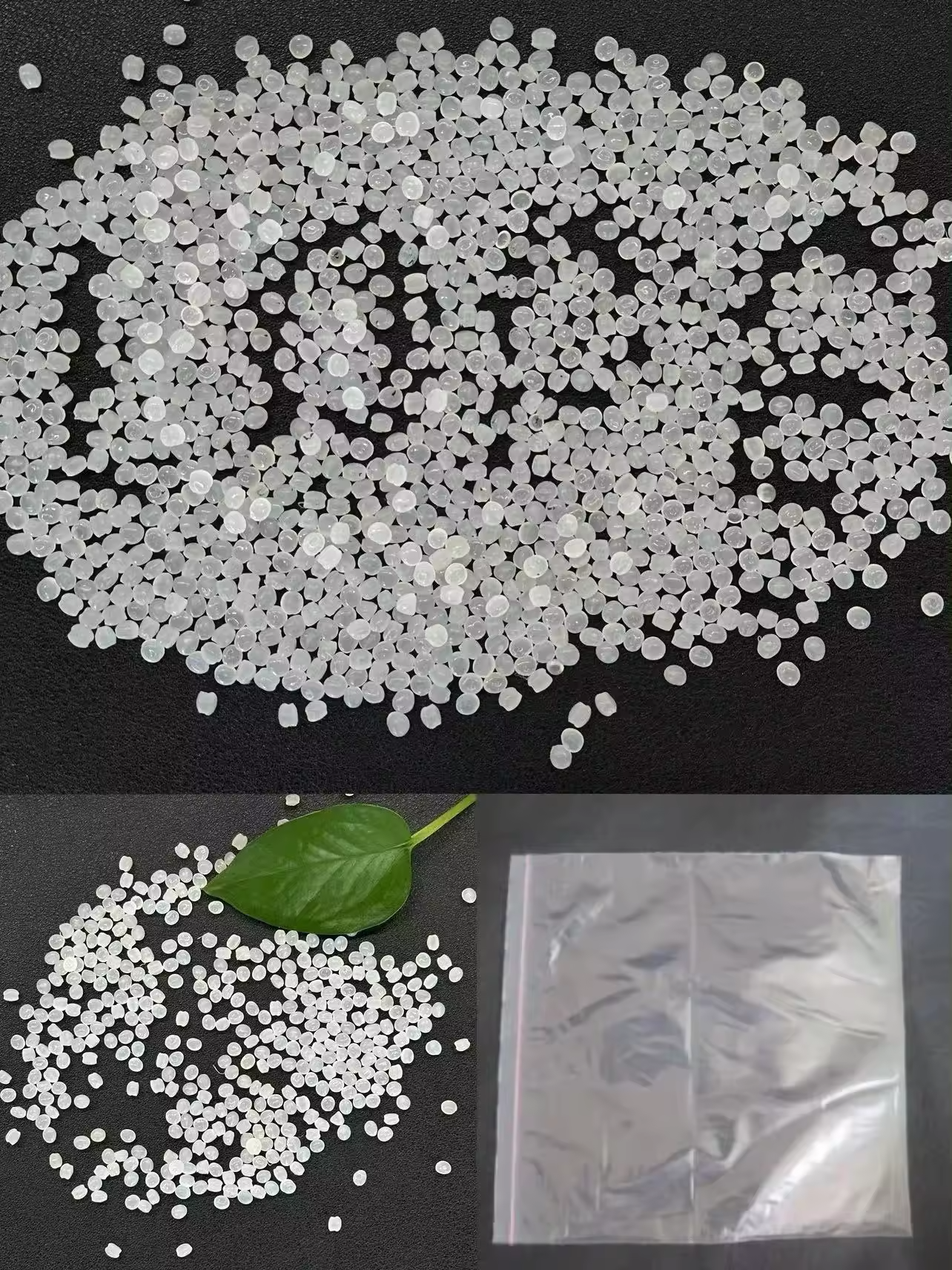

Low density polyethylene, also known as high-pressure polyethylene (LDPE), is the lightest type of polyethylene resin. It is a milky white, odorless, odorless, non-toxic, and non glossy wax like particle. It has good flexibility, elongation, electrical insulation, transparency, ease of processing, and certain breathability. It has good chemical stability, alkali resistance, and resistance to general organic solvents.

The main characteristics of low-density polyethylene are as follows:

(1) The film has a slightly milky white transparent color and is soft. The strength is smaller than that of high-density

polyethylene, while the impact strength is greater than that of high-density polyethylene.

(2) Cold resistant, low temperature resistant, and high temperature resistant. The thicker film can withstand the

sterilization process of soaking in 90 ℃ hot water.

(3) Good moisture resistance, stable chemical properties, and insoluble in general solvents.

(4) Due to its high breathability, the storage period of its contents should not be too long when used as food packaging

that is prone to oxidation.

(5) Poor oil resistance, the product can be slowly dissolved and swollen. When packaging food containing fats and oils,

long-term storage can cause the food to have a pungent taste.

(6) Long term exposure to ultraviolet radiation and heat can cause aging, affecting its physical and dielectric

properties.

(7) The melting point is 110~115 ℃, and the processing temperature is 150~210 ℃. If in an inert gas, the temperature can

reach 300 ℃ and remain stable. But the contact between the melt and oxygen is prone to degradation.

Advantages of LDPE

Low density polyethylene is the lightest variety among polyethylene resins. Compared with high-density polyethylene, its crystallinity (55%~65%) and softening point (90~100 ℃) are lower; Has good flexibility, extensibility, transparency, cold resistance, and processability; It has good chemical stability and can withstand acid, alkali, and salt aqueous solutions; Has good electrical insulation and breathability; Low water absorption; Easy to burn. Soft in nature, with good extensibility, electrical insulation, chemical stability, processing performance, and low temperature resistance (can withstand -70 ℃)

application

LDPE is mainly used for film products, such as agricultural films, ground covering films, agricultural films, vegetable greenhouse films, etc; Packaging with films such as candy, vegetables, frozen foods, etc; Blow molded film for liquid packaging (milk, soy sauce, fruit juice, tofu, soy milk); Heavy packaging bags, shrink packaging film, elastic film, inner lining film; Architectural films, general industrial packaging films, and food bags. LDPE is also used for injection molded products, such as small containers, lids, daily necessities, plastic flowers, injection molded stretch blow molded containers, medical equipment, pharmaceutical and food packaging materials. Extruded pipes, sheets, wire and cable coverings, profiles, hot formed products, etc; Blow molded hollow molding products, such as food containers such as milk products and jam, medicine, cosmetics, chemical products containers, tanks and other calcium plastic plates, foam plastics, etc. Rotational molding products are mainly used for large containers and storage tanks.

| Place of Origin | Hebei, China |

| Brand Name | LIGUAN |

| Grade | blow molding grade, extrusion grade, blown film grade, injection molding grade |

| Feature | low temperature resistance, High impact resistance, standard grade, transparent grade, High Gloss |

| color | Semi transparent, milky white |

| Shape | Granules Pellets |

Hebei

Liguan Trade Co. , Ltd. was established in 2021 and is a leading company specialized in producing

plastic

and rubber particles, such as HDPE, LDPE, LLDPE, EPS, PEEK EVOH, PA, PS, EVA, ABS, PVC. . . . . So far,

we

has operations in 35 countries. The product quality has always been the best among Chinese suppliers.

Relying on a comprehensive quality control system and professional advanced production equipment, we are

able to actively meet the constantly changing needs of customers.

Q1. Why choose us?

We are established 2021 and we offer very competitive prices for all our products.

Q2. What can you buy from us?

HDPE, LDPE, LLDPE, PP, GPPS, HIPS, ABS. PET, EVA, PVC, PVC RESIN, PC, TIO2 ETC.

Q3. What's the delivery time?

7-15 days. Only when the quantity exceeds 50 tons delivery time will be agreed by negotiations.

Q4. About the payment?

T/T or Western Union.

Q5. About the Quality?

All products must be tested in strict accordance with the test procedures before they leave the factory

Copyright © Hebei Jiafan Trading Co., Ltd. All Rights Reserved