EN

EN

Request A Quote Questions & Comments After Sales Services Resource Center

EN

EN

Request A Quote Questions & Comments After Sales Services Resource Center

Why ABS Resin Material is the Best Choice for Your Next Project

Looking for strong a Material, versatile, and safe? look no other further than ABS Resin Material. This amazing abs resin material has so several benefits that make it the perfect choice your next project. We shall explore advantages, innovation, safety, usage, and quality of JIAFAN ABS Resin Material.

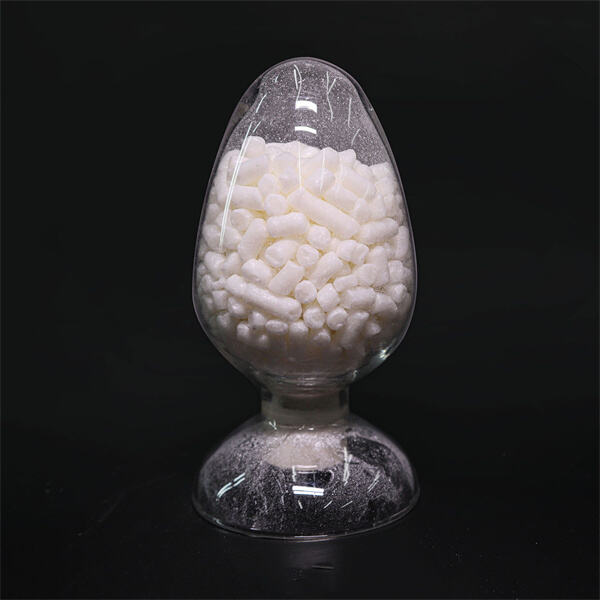

The material is normally lightweight, rendering it easy to carry out and transport, and has now a low manufacturing, which makes it affordable for a true number of projects. It is manufactured out of a blend of three different plastics: acrylonitrile, butadiene, and styrene. ABS Resin Material is merely a thermoplastic polymer is fabled for its durability and power. One of the numerous significant advantages of abs plastic resin from JIAFAN is being resistant to heat and chemical substances, which makes it perfect for applications where these factors are a problem.

One when it comes to many exciting innovations the capacity to create custom colors and finishes, allowing for more creative and unique designs. The abs resin material by JIAFAN may be molded into complex shapes and patterns, giving developers more freedom to produce the perfect merchandise their needs. ABS Resin Material has been utilized on the certainly market decades automotive but new innovations in the Material are making it more versatile than ever before.

Safety is obviously a problem when working together with any Material, but pc abs resin manufactured by JIAFAN is understood if you're among the safest plastics in the marketplace. It's also commonly used in items that will come into connection with meals, such as kitchen area machines and utensils, due to the food-safe official certification. It is non-toxic and does not emit harmful gases making it safe to be used in a wide variety.

ABS Resin Material is easy to make use of and may also be molded into many shapes which will vary sizes. The Material is usually processed utilizing injection, but other methods, such as blow molding and extrusion, may be utilized also. To use hdpe resin, the first step is always to produce a mildew here is the shape and size for this last item. The mold is then full of molten JIAFAN ABS Resin Material, which cools and solidifies into the desired form. This last system then be finished with custom colors and finishes.

The company was established in 2017 and specialize producing the rubber and plastic particles. We able to meet the abs resin materialcustomers by providing various grades of plastic raw material granules such as film grade, extrusion grade, coating grade optical grade, food contact grade. Our factory is awash knowledge and a strong physical strength. We have a variety of mills and granulators which have an annual production of 5000 tons.

We're dedicated delivering top-quality products and service after sales, which will help abs resin materialthe goal of reducing costs, improving efficiency, providing timely and quality supply, and make significant contributions to the rapid growth of the company. Continuously offer high-quality service assurance enhance our service. Always put the needs of customers first .

We offer our products many countries across the globe, including Northern Europe, Southeast Asia North America. The transportation of goods can be accomplished via air, sea or by land. Our customers from all over world have abs resin materialour logistics service as quick, easy secure, and efficient.

Our primary business producing and selling plastic abs resin material. Currently our main products include allEVA EVOH PCTG PESU POE PC ABS PEEK PVC PVA HDPE LDPE PP EPS GPPS Paraffin and other plastic granules.We also accept customized production (sample customization/parameter customization).

Copyright © Hebei Jiafan Trading Co., Ltd. All Rights Reserved